- What is 3D printing, and how can it work?

3D printing, otherwise called added substance fabricating, is an interaction where computerized models are transformed into actual items by layering materials like plastic, metal, or sap. This innovation fabricates objects layer by layer in view of a PC helped plan (computer aided design) model, empowering exact and complex shapes.

- How does 3D printing benefit prototyping and item improvement?

3D printing speeds up prototyping by permitting fast making of actual models straightforwardly from computerized plans. This makes it simpler to test ideas, make plan cycles, and diminish time to showcase. It additionally permits creators to imagine, test, and refine items prior to resolving to full-scale creation.

- What are the expense saving benefits of 3D printing?

3D printing lessens costs by killing the requirement for costly molds, tooling, and conventional assembling processes. It takes into account on-request creation and decreases squander by just utilizing the important measure of material. More modest creation runs become more conservative with 3D printing contrasted with conventional techniques.

- How does 3D printing improve customization and personalization?

3D printing empowers the making of modified items custom fitted to explicit requirements or inclinations. Whether it’s customized gems, custom clinical gadgets, or made-to-fit parts, the innovation takes into consideration mass personalization at practically an additional zero expense, giving a one of a kind answer for buyers.

- Which job does 3D printing play in lessening waste and advancing maintainability?

Not at all like conventional assembling, which frequently includes removing material from bigger blocks, 3D printing is an added substance process that forms objects layer by layer, limiting waste. Also, it can utilize eco-accommodating materials, and the capacity to encourage parts on interest lessens the requirement for abundance stock, further supporting reasonable practices.

- How might 3D printing further develop inventory network effectiveness?

3D printing empowers on-request creation, which diminishes the requirement for enormous inventories and long lead times in the production network. It permits organizations to make parts locally, reducing down on transportation expenses and deferrals. Besides, the capacity to create spare parts and instruments rapidly further develops upkeep productivity and diminishes margin time.

- What businesses benefit most from 3D printing innovation?

A few ventures benefit from 3D printing, including medical services (for prosthetics, inserts, and careful models), auto (for prototyping and lightweight parts), aviation (for complex parts and devices), style (for modified plans), and development (for building designs and custom parts). Its flexibility makes it pertinent across many fields.

- How does 3D printing add to advancement and plan adaptability?

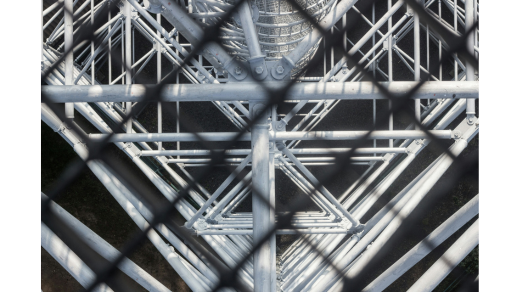

3D printing permits fashioners and specialists to explore different avenues regarding complex calculations and designs that would be incomprehensible or costly to make with conventional strategies. This adaptability supports development, empowering the making of lighter, more grounded, and more effective plans that upgrade item execution and usefulness.

3D printing innovation offers various advantages, from lessening expenses and waste to empowering quicker prototyping and customization. Its applications keep on growing, adding to progressions in different enterprises and encouraging more feasible assembling rehearses.